| |

|

Overview •

Details

• Specifications

Overview •

Details

• Specifications |

|

FC7000 |

|

|

The most advanced and sophisticated

multi-functional cutting plotter technology for plotting, cutting and

pouncing applications is available in 30", 42", 54" and 64" widths, with

maximum compatible media widths of 36", 48", 60", and 72" respectively.

The FC7000 series is ideal for anyone involved in post dgital imaging

processes such as die/contour cutting. |

|

|

Free Media Basket

For a limited time, Graphtec is

offering a free media basket with any FC7000 series purchase!* The

media basket facilitates dust-free cutting/plotting operations and

enhanced media tracking for long, continuous project applications.

The collapsible front and rear baskets keep the media off the shop

floor to prevent dust and residue from accumulating on the output

material. This feature is ideal when unevenness and/or obstacles are

observed in the media pass (on the floor) that can potentially

affect the plotter's tracking performance.

* Offer valid for purchases

made between July 18 thru October 14, 2005. Allow 4-6 weeks for

delievery. |

|

|

STANDARD PERFORMANCE FEATURES:

|

|

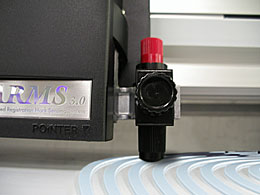

The Advanced Auto-registration

mark sensor is included as a standard feature for all FC7000 models.

The RMS system detects the

registration marks printed alongside digitally produced images to

automatically align preprinted images to the internal coordinate

system and even compensate for material expansion/contraction. The

RMS system's user interface has also been enhanced, making it

extremely user-friendly and accurate. These intelligent features

assure users of unsurpassed accuracy and consistently reliable

operation for the most intricate die/contour cutting applications. |

|

|

| SMOOTH

AND ACCURATE CUTTING/PLOTTING WITH PROLONGED TOOL LIFE |

|

|

Improved cutting/plotting quality

and prolonged tool life are just a few of the outstanding standard

features you can expect from the FC7000 series, made possible by the

innovative Tool Soft Landing Intelligence. The Graphtec proprietary

closed-loop servo actuator, with an integrated precision sensor,

ensures quick, precise, yet gentle tool contact with the material

surface during up and down motions. In addition to superior and

accurate output, the Soft Landing feature prolongs the life of the

cutting/plotting tool and maximizes throughput performance. |

|

The innovative Tool Soft Landing

Intelligence provides not only consistent and optimum cutting

quality throughout the job, but also the benefit of cost-saving tool

maintenance. |

|

|

INDUSTRY-LEADING CUTTING SPEEDS |

|

Featuring maximum programmable cutting

speeds of 58.5 ips, 4.0G maximum acceleration and 20 to 600g cutting

force, the FC7000 series accommodates the most demanding cutting and

plotting projects, while providing users with the versatility they need

for a wide variety of applications. With the world's fastest throughput

performance and superb accuracy, the new FC7000 performs highly

intricate cutting as small as 1/16" high text on vinyl. The innovative

technology incorporated in this series helps users accomplish numerous

applications in a limited timeframe, thereby increasing their overall

profit. |

|

The Accuload™ Media Supply System

integrates a media-aligning guide to assist both new and experienced

users in loading and aligning the media accurately for assured

tracking performance. It allows effortless loading of media from

tightly wound fresh roll, manually rewound loose roll, or cut-sheet

form. The new Accuload™ for the FC7000 series also incorporates a

cross cutting groove for enhanced user-friendliness. The convenient

cross cutting groove provides a simple solution for obtaining a

straight sheet cut-off of your finished job, making it easier than

ever! |

|

|

|

USER FRIENDLY FEATURES: |

|

PLUG-IN SOFTWARE INTEGRATES

WITH POPULAR GRAPHIC/ILLUSTRATION SOFTWARE

Cutting MasterTM plug-in software

is included with the FC7000 series and facilitates

output of designs directly from Adobe Illustrator®, making it easy

to integrate an economical sign-making system. The standard

Automatic Registration Mark Sensor system is included for precision

contour/die cutting of digitally printed images. |

|

EASY

TO USE CONTROL PANEL

The user-friendly

control panel comes standard with a large 20-digit x 4-line LCD

information display and icon-labeled comprehensive controls,

providing effortless operation and simple navigation of various

setup menus. The oversized LCD allows users to quickly glance at all

operational conditions including equipment status, speed, force,

quality (acceleration) and type of tool with pre-programmed offset

value. |

|

Eight commonly used

function controls including: instantaneous Hold (Pause),

Cutting/plotting Conditions, Axis/RMS Alignment, View,

Position, Copy, Test Cut, and New Origin are

directly accessible on the control panel for added user-efficiency. The

pressure-sensitive dual-speed position keys enable expeditious tool

positioning with high accuracy.

8 user-programmable settings facilitate frequent switching among

application specific plotter setups and material selection. Each setting

can be programmed with the specific type of tool (blade, pen, pounce

tool or LED beam), cutting/plotting speed, acceleration, force,

tangential control and distance compensation required for a specific

application. These settings provide the user with an instaneous recall

of pre-programmed setup conditions for varying job requirements, further

increasing job efficiency and productivity. |

|

SOPHISTICATED TANGENTIAL EMULATION OUT

CUTS OLD-FASHIONED MECHANICAL TANGENTIAL SYSTEMS |

|

When the Tangential

Control mode is engaged, the FC7000 over-cuts the mechanical

tangential system both in speed and output quality by precisely and

intelligently controlling the blade rotation. The on-board tool

height sensor detects the blade tip's landing on the media surface,

then intelligently and precisely aligns the blade rotation for the

following cutting operation, all in a fraction of a microsecond.

Graphtec's proprietary technology allows this sophisticated feature

to completely eliminate distorted, rounded, or lifted corners - even

when highly intricate design cutting is required on 2 mil. vinyl

film or up to 50 mil. sandblast rubber. This innovative and high

precision system architecture is what enables the FC7000 to cut text

strings as small as 1/16" on vinyl. There is no other cutter/plotter

on the market that can match the FC7000 series' unsurpassed

precision and built-in intelligence. |

|

|

|

ENHANCED MECHANICAL INTEGRITY FOR

QUALITY AND PERFORMANCE |

|

|

The all-new mechanical design

incorporated in the chassis and electro-mechanical components

further improve the FC7000's structural integrity, resulting in

high-quality output, unsurpassed reliability, and media tracking

performance.

Engage the SmartFeed™

auto material pre-feed function to further enhance the FC7000

series' tracking capability for long-length and repetitive

cutting/plotting operations. Built-in SmartFeed™ intelligence

automatically unwinds the media roll and pre-feeds it for a

user-programmable length as the plotting data extends beyond the

prepared area. |

|

|

CONNECTIVITY AND SOFTWARE |

The FC7000 supports tri-port connectivity with

serial, parallel and USB interface ports, providing compatibility with

virtually any computer configuration. The standard package includes:

- A Windows driver compatible with Windows® 98, ME,

2000, and XP; supporting serial, parallel and USB port connectivity

- Adobe® Illustrator® Cutting Master™ plug-in

software compatible with Windows® 98, ME, 2000, XP or MAC® OS 8, 9,

10(X); supporting USB connectivity

|

|

Optional Features... |

-

Stand Integrated Media Racks

Maintain up to 3 extra full-length rolls conveniently at the foot

of your plotter. The media rack option enhances job efficiency and

productivity by allowing you to quickly switch between media rolls

or directly feed material from the rack. Each optional rack holds

one full-length roll of media for easy, quick roll exchange and

allows you to switch between media color, type, and size with

minimal effort.

|

|

|

|